| Model | Carrier Weight | Shank Thickness (mm) | Working Depth (mm) | Tooth Type | Side Protection | Front Protection | Rear Protection |

|---|---|---|---|---|---|---|---|

| 010-RP | 1-2 Tonne | 30 | 371 | J200 | X | X | X |

| 020-RP | 2-3.5 Tonne | 30 | 371 | J200 | X | X | X |

| 040-RP | 4-6 Tonne | 40 | 479 | J200 | ✓ | ✓ | X |

| 060-RP | 6-9 Tonne | 50 | 596 | J250 | ✓ | ✓ | ✓ |

| 100-RP | 10-14 Tonne | 60 | 674 | J300 | ✓ | ✓ | ✓ |

| 150-RP | 15-18 Tonne | 70 | 945 | J350 | ✓ | ✓ | ✓ |

| 200-RP | 18-24 Tonne | 80 | 990 | J350 | ✓ | ✓ | ✓ |

| 250-RP | 25-30 Tonne | 90 | 1180 | J350 | ✓ | ✓ | ✓ |

| 300-RP | 30-40 Tonne | 90 | 1240 | J400 | ✓ | ✓ | ✓ |

6-9 Tonne Excavator Ripper Hook

Couldn't load pickup availability

Need Help?

Our friendly Support Team can be reached from 9 am to 5 pm (GMT), Monday through Friday to assist you with your order.

☏ 01525 851912

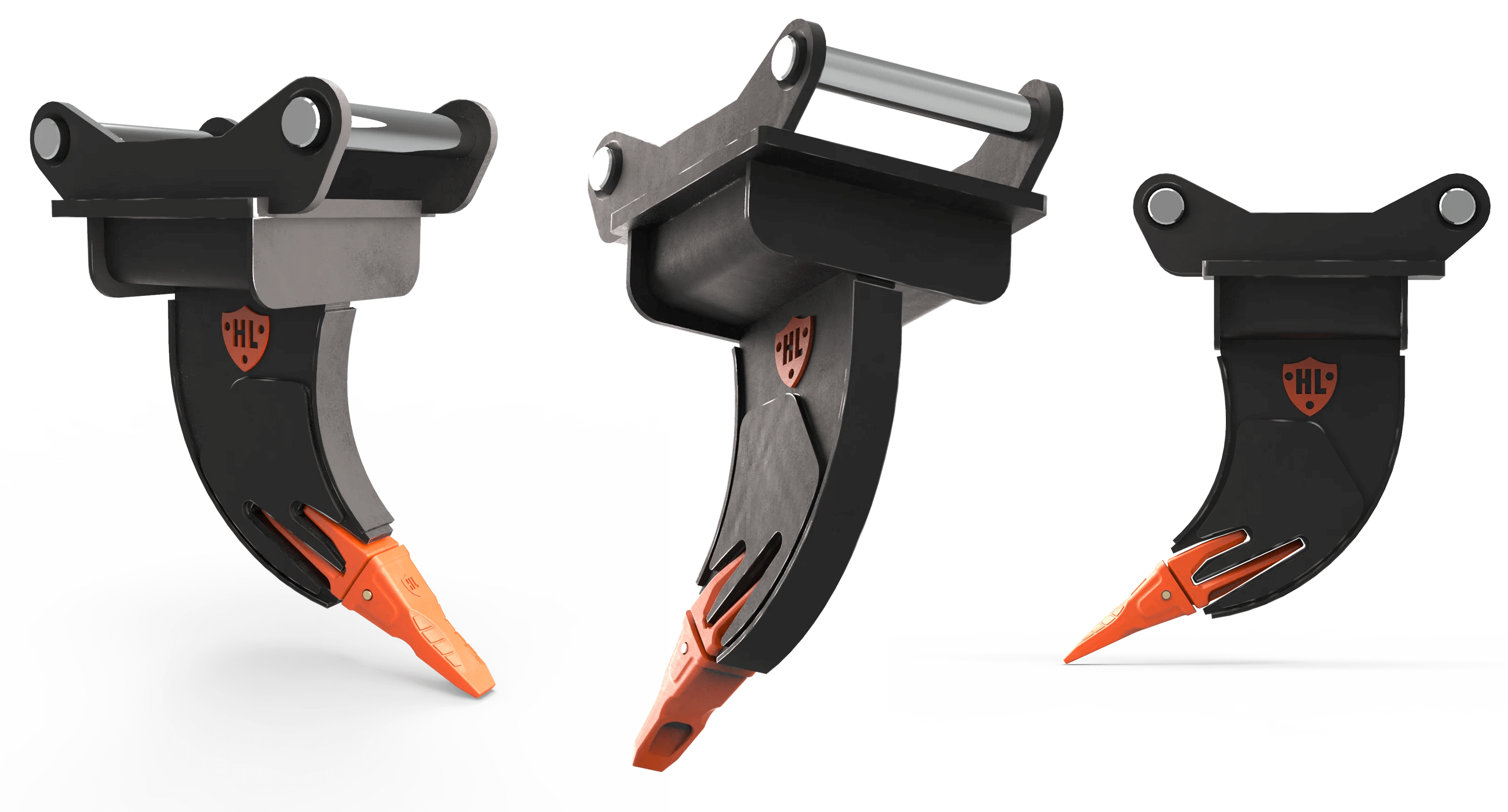

Our ripper hooks are heavy duty attachments designed for use in hard wearing environments and for applications such as rock digging, quarrying, excavating and demolition. Our ripper hooks are fitted with CAT type tooth points, which are highly popular and widely available in a number of different shapes.

Ripper claws allow all the machine's power to be focused through one point for maximum breakout force. As you can concentrate the power you actually put less strain on your machine as the smaller surface area means easier penetration than with a bucket, for instance.

Features

Any Linkage Supplied

Our rippers are available with any linkage required to fit your excavator.

Effective Design

Our ripper has the tooth point angled at 30° to ensure that, when crowding, the main stresses are concentrated right through the centre of the tooth and the

ripper shank. This ensures strength for ripping power, but also longevity of the ripper itself.

Lateral Support

Box section strengthening at top of our ripper with double weld points ensures continuous counteraction of the constant leveraging forces applied through the excavator during use.

Shaft Protection

Abrasion resistant steels have excellent durability and are

incredibly tough, so they’re able to withstand abrasion and will hold their shape for longer. On our ripper, we use AR HB400 grade steel to protect the sides, the back and the leading edge of the ripper shank. These vulnerable

areas experience more wear and so the hardened steel is there to stop shape deformation and ensure durability.

Tooth

Hardened abrasive cast tooth system offers maximum ground penetration.

Need a hand? Or just more info?

Our friendly Support Team can be reached from 9 am to 5 pm (GMT), Monday through Friday to assist you with your order.